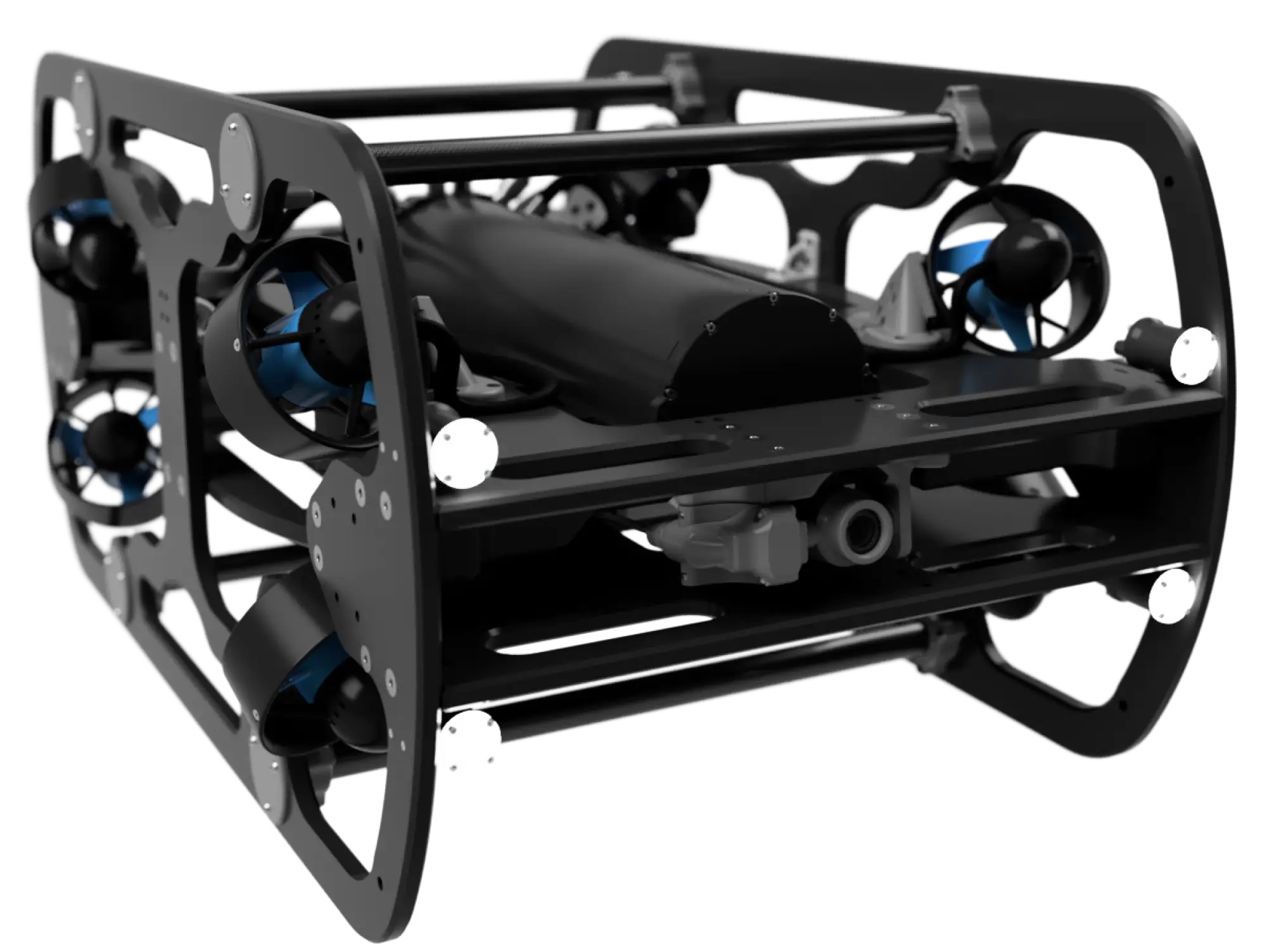

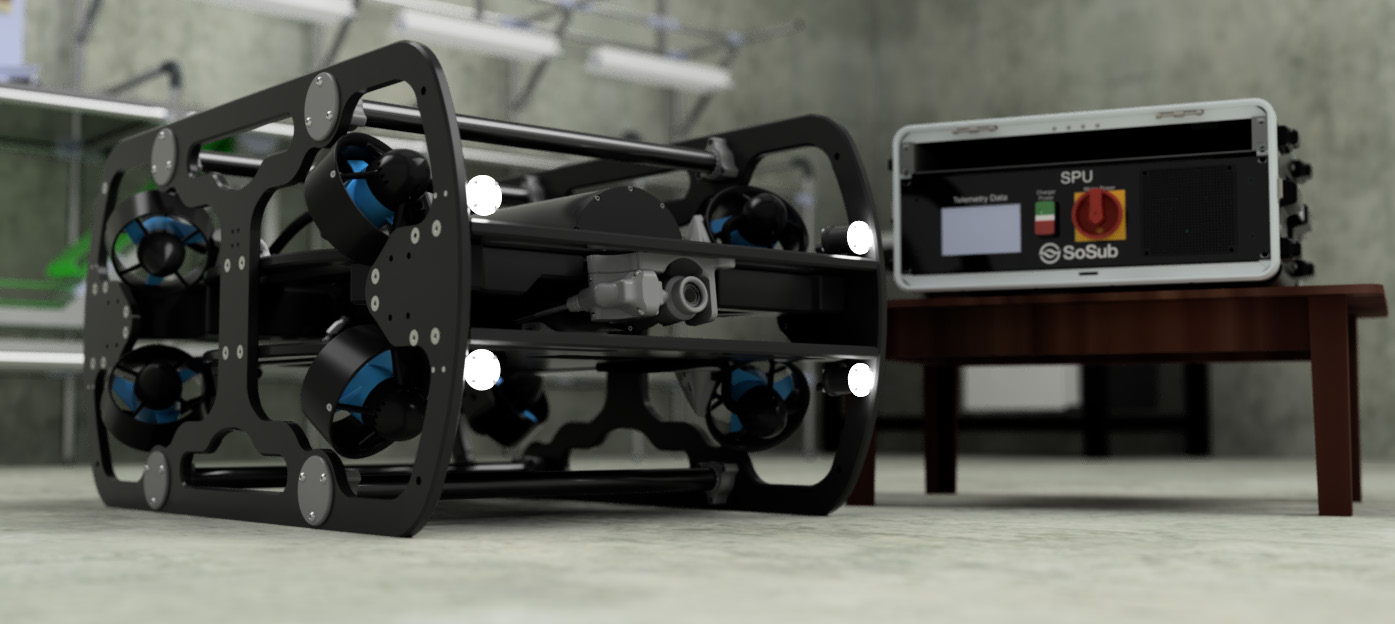

APAMA ROV

APAMA Features

Environmental Sustainability

On-Demand Inspection and Repair

Precision Underwater Stitching

Advanced Control System

Adaptability to Harsh Conditions

Innovative Design

cutting-edge without full replacements.

Six Degrees of Freedom

Seamless In-Situ Repairs

Safety and Efficiency

Capabilities of the APAMA ROV

Pressure Cleaning with Retrojet Cleaning System

The APAMA ROV has revolutionised pressure cleaning in challenging underwater environments. One of our clients leverages the ROV to clean skeletal structures on the exteriors of barges, achieving faster, safer results compared to traditional diving methods. Moreover, we’ve successfully deployed this solution alongside hydro and water companies to pressure clean sealing surfaces at depths too deep for divers. This approach also eliminates the need for costly shutdowns, which would otherwise be necessary to ensure diver safety in hazardous areas.

Fish and Predator Net Inspections

In the aquaculture industry, the APAMA ROV has reduced inspection times by nearly 50%. This efficiency is driven by our advanced 6-DOF intuitive control system, allowing for precise and agile manoeuvring. Coupled with an intuitive controller developed in collaboration with end users, operators have full control to orient the ROV in any required position, ensuring tasks are completed efficiently. This combination of advanced control and user-friendly design has been highly praised, significantly enhancing operational productivity when navigating complex net structures.

Net Repair with Patented System

During inspections, when a hole is detected in the net, the APAMA ROV is equipped to perform permanent repairs on the spot. Our patented net repair system has demonstrated a 95% success rate in fixing various types of holes, according to data from clients using the system. While this system is still in its final development stages, it is poised to set a new global standard, potentially eliminating the need for traditional dive-based net repairs.

Rope Cutting Capability

We have developed a prototype electronic rope cutter specifically designed for the APAMA ROV, capable of cutting mooring lines up to 80mm in diameter. The cutter excels on Dyneema ropes, renowned for their strength and durability. To our knowledge, this tool is the smallest in the world capable of handling ropes of this thickness, showcasing the APAMA ROV’s advanced capabilities in marine operations.

Why the APAMA ROV stands out in the industry

Hybrid Power System

The APAMA ROV features a unique hybrid power system, enabling indefinite operation on surface power. In the event of a power failure, the ROV can continue operating for an additional 1-2 hours on its own battery power. This capability allows us to send an average amount of power down the tether, avoiding the need to manage peak loads. Consequently, the surface power supply only needs to be 2 kW, making the system both efficient and reliable in various operational scenarios.

Lightweight and Robust Design

Traditional ROVs often struggle with excessive weight. We’ve engineered the APAMA ROV using a lightweight yet robust material called foamed PE, reducing the ROV’s weight to just 40 kg. This design makes deployment and operation much easier without compromising durability

Modular and Repairable Components

Recognising that components like thrusters, lights, and cameras are susceptible to wear and tear, we’ve designed the APAMA with field-replaceable connectors for these parts. This modular approach ensures maintenance can be performed quickly and efficiently, minimising downtime.

Open Frame Design

The APAMA features an open frame design, facilitating the easy mounting of various payloads and sensors. This flexibility allows users to customise the ROV for a wide range of applications, from routine inspections to complex research missions.

3D Printed End-Use Parts

In collaboration with Formlabs, we’ve integrated advanced 3D printing techniques into the APAMA’s design. This innovation includes 3D-printed pressure vessels tested to depths of up to 850 meters. The use of 3D printing not only allows for rapid production and global distribution of parts but also enables quick customisation to meet specific client requirements, whether it’s a simple bracket for a tool or a specialised pressure chamber for unique sensor payloads.

The APAMA ROV is more than just an underwater vehicle; it is a solution crafted from years of industry insight, designed to overcome the limitations of traditional ROVs and set a new standard in underwater operations.

Who we are trusted by

Looking to start a new project?

In the boundless depths of the ocean, every connection matters. At SoSub, we’re excited to solve the unsolvable. Your questions fuel our innovation. Get in touch with us to explore the possibilities.